Moreover, such an expense is a crucial factor in determining the sales price of goods. Therefore, it is critical for cost management in manufacturing companies where minimizing the factory overheads results in higher profits, ensuring overall operational efficiency. When considering the total manufacturing cost, it’s important to factor in how machinery shipping services impact overall expenses. Transporting equipment efficiently ensures timely production and curbs potential delays. Types of transport, such as flatbed trailers for large machinery, are vital when accommodating unique equipment sizes. Custom part manufacturing is a demanding industry that uses a wide variety of machines, materials, and processes to provide custom component solutions.

Total Manufacturing Cost: Formula, Calculation & Ready-to-Use Template

Furthermore, Total Manufacturing Cost differs from what are total manufacturing costs the costs of goods (COGS). Be sure not to underestimate any of your expenses for those three categories. Small details that may only amount to small expenses can still collectively make a big impact on your business. Producing too much stock in advance means you are spending a lot more on direct material costs.

Understanding the Costs in Product Costs

These can include indirect labor costs, such as wages for supervisors and the material handling team. Indirect materials costs are also part of manufacturing overhead, such as the purchase of lubricants, grease and water that aren’t used as raw materials. Calculating production costs involves a comprehensive assessment of all expenses incurred during the production process. Start by identifying and summing up direct costs, which include direct materials and direct labor. For accuracy, it’s essential to regularly update cost data and adjust for market changes or operational efficiency improvements. Your business’s total manufacturing overhead summarizes the indirect costs of producing finished goods.

Determining Direct Materials Used

The tax code is complicated, and it can be hard to keep up with what’s changing in the laws and regulations, especially regarding business taxes. But manufacturers must stay on Accounts Receivable Outsourcing top of these changes because they can make a massive difference in the bottom line. Sustainability in production also enhances brand reputation and can attract customers who value eco-friendly practices.

It’s important to factor in both your direct and indirect costs when using the total manufacturing cost formula. In summary, direct material costs are not only about numbers—they represent the tangible essence of the products we create. By managing them effectively, businesses can enhance profitability and deliver high-quality goods to their customers. Company X, a bicycle manufacturer, sources aluminum alloy tubes for its bike frames. The direct material costs include the price of the tubes, any waste during cutting and shaping, and quality control checks. If the supplier increases tube prices, Company X must adjust its cost calculations accordingly.

Workers like janitorial staff and supervisors all play an essential role in the success of your business, but they are considered “indirect labor” for the sake of these calculations. Cost of Goods Manufactured (COGM) is a term used in managerial accounting that refers to a schedule or statement that shows the total production costs for a company during a specific period of time. Just like the name implies, COGM is the total cost https://bellaflor.com.uy/contribution-margin-what-it-is-and-how-to/ incurred to manufacture products and transfer them into finished goods inventory for retail sale. You’re probably wondering what all those terms mean, and we’ll get to that. But before talking about the total manufacturing cost formula, it’s essential to know about direct and indirect costs. When scaling production, the cost of raw materials can exhibit a promising trend.

Overhead Costs

- The higher your production costs, the thinner your profit margins are likely to be.

- For instance, if a company had $10,000 in raw materials, purchased an additional $5,000, and ended with $3,000, the direct materials used would be $12,000.

- 1) The Average Calculator from Smart Tools AI helps you quickly determine average costs across production runs.

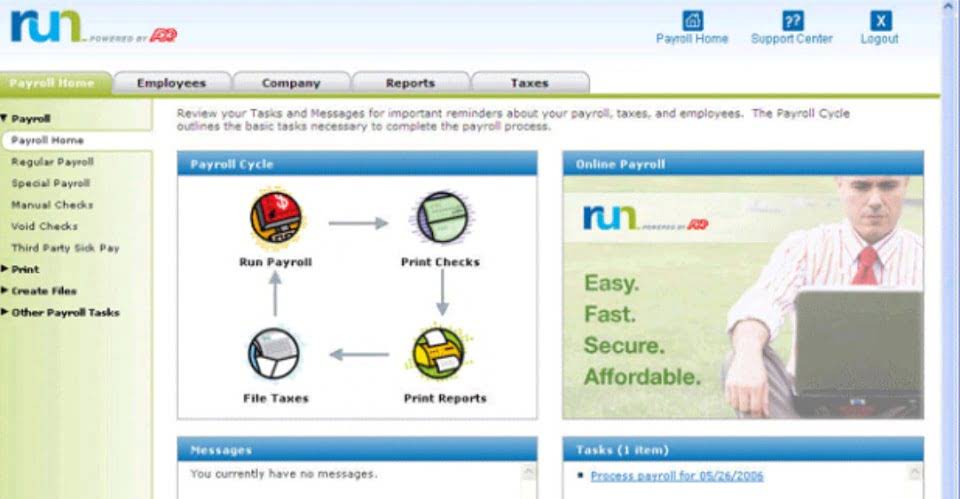

- The basic formula to determine a company’s total manufacturing cost is to add up the expenses for direct materials, labor, and overhead incurred during a given production run.

- For example, if Company A is a toy manufacturer, an example of a direct material cost would be the plastic used to make the toys.

- Efficient SCM involves optimizing logistics, inventory management, and supplier relationships to minimize material costs, reduce lead times, and enhance overall operational efficiency.

It gives you a clearer picture of your expenses, and from there, you can make better decisions to cut costs, improve processes, and ultimately boost profitability. Unless you keep track of manufacturing costs, there’s no way to know if you hit the revenue targets or suffer a loss following a production period. Here’s a detailed guide about everything you need to know about TMC and its importance.

Combining these figures, the total manufacturing cost for the dining table set is \$1,130. It’s important to distinguish between direct and indirect manufacturing costs. When business costs relate to production activities they are generally classified as ‘direct’ or ‘indirect’.